The process of toilet paper production from finished tissue into consumer’s rolls:

Installation of tissue paper roll on the rewinder.

Tissue rewinding into consumer’s rolls.

Technological roll paper labeling.

Technological roll cutting into consumer’s rolls.

Consumer’s roll packaging.

WE RECOMMEND USING THE SUPPORT EQUIPMENT TO REDUCE DOWNTIME:

LABELING

The labeling-collecting table.

It enables to eliminate the loss of time for technological roll carry-over (operator passages between machines).

The labeling machine.

It makes log labeling fully automatic.

The measuring label cutter.

It enables to cut a label (up to 30 pcs.) to a desired size during 1 minute.

PACKAGING

The packaging table.

It makes easier and speeds up the process of consumer’s roll packing into bags.

The packager.

It makes finished roll packing into bags fully automatic.

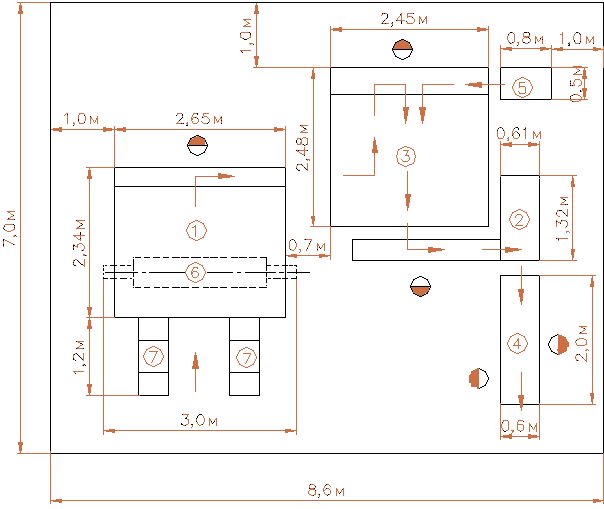

Equipment layout for toilet paper production from finished tissue:

- Tissue paper rewinding equipment.

- Toilet paper cutting equipment.

- Labeling-collecting table (Labeling machine).

- Packaging table (Packaging machine).

- Measuring label cutter.

- Tissue roll.

- Rolling ramp.

workstations (only for semi-automatic equipment).

workstations (only for semi-automatic equipment).

process flow direction.

process flow direction.

TRAINING

On the basis of our company

1 to 3 days

free of charge

GUARANTEE

Guarantee maintenance

6 months

from a date of sale

SALE

At the buyer’s

request, the individual line

elements can be sold