Core winding machine

Core winding machine

AUTOMATIC CARDBOARD CORE WINDING MACHINE

Purpose of the equipment:

Production of 2-, 3-, 5-layered cardboard cores (sleeves) of different diameter and length. Cores serve as a basis for winding paper, polymeric film products, foil, food package, cardboard, scotch tape.

Specifications:

- diameter: 20-90 mm;

- wall thickness: 0.5-2 mm;

Description:

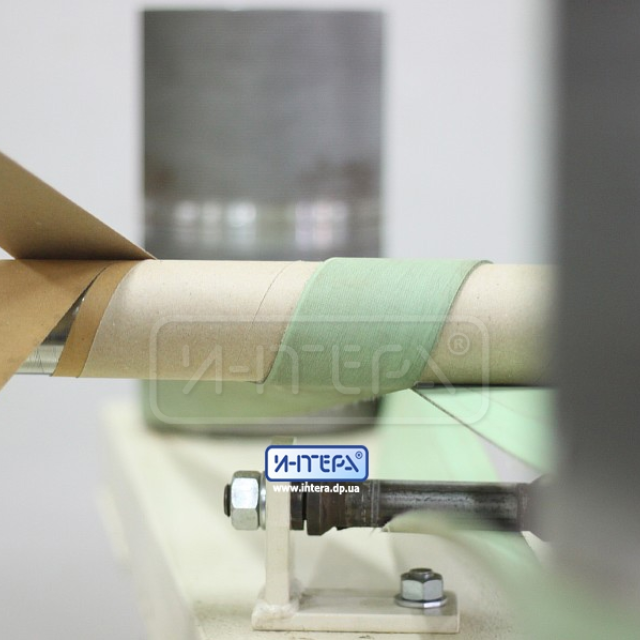

Core production is carried out by a method of continuous spiral winding of a cardboard belt on rods of different diameter.

Non-stop spiral winding, cutting unit is moved together with the cut core. Core length is adjusted from 1m to 3m.

Features:

- winding speed adjustment;

- cut zone is covered by a protective housing;

Specifications:

- capacity: up to 30 m/min;

- width of a cardboard belt: 30-100 mm (depending on the wound diameter);

- cardboard density: 150-220 g/m²;

- diameter of belt roll: up to 1000 mm;

- internal diameter of core: 20-90 mm;

- wall thickness: up to 2 mm;

- length of the cut core: from 1000 mm;

- total power: 2.5 kW;

- voltage: 380V / 50Hz;

- air pressure: 6 bar